With precision and innovative processes, the employees fuse more than 20 natural raw materials such as quartz and feldspar with steel to create Fusiontec, WMF's outstanding cookware.

DEEP-DRAWING

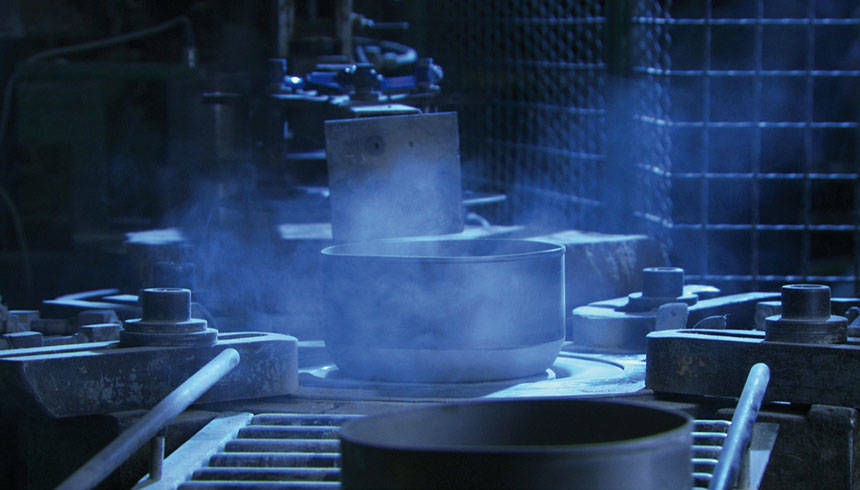

The special steel core made of almost pure iron is moulded through a deep-drawing process.

CHROMINGThe pouring rim is produced by polishing and plating process, after that it is sealed with chromium to protect it from corrosion and chipping off.

QUALITY CONTROL The handles are then assembled and a final 100% quality control is executed by hand.

*The 30-year warranty covers the inner and outer surface of Fusiontec cookware and applies only if the product is used as in-tended. Details of the scope of the warranty and about proper use can be found in the instruction manual enclosed with the products.

**based on scientific literature and internal tests, 2020

**based on scientific literature and internal tests, 2020